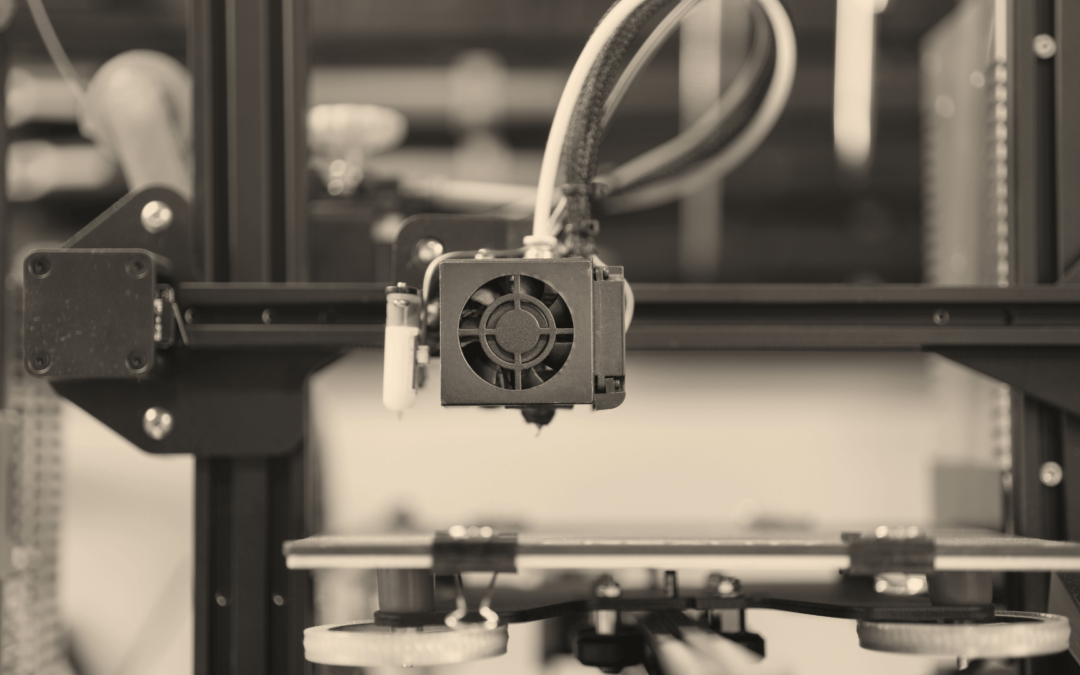

In the ever-evolving world of manufacturing, speed, flexibility, and precision are no longer just advantages, they’re requirements. That’s why companies at the forefront of innovation, like KIMASTLE, are embracing 3D printing to transform the way plastic assembly automation is designed and delivered.

At KIMASTLE, we’re leveraging advanced 3D printing technologies, specifically Fused Deposition Modeling (FDM), to push the boundaries of what’s possible in plastic assembly automation. From rapid prototyping to customized tooling and automated assembly solutions, 3D printing is helping us deliver innovative solutions faster and more efficiently.

Fast-Track Prototyping with Fused Deposition Modeling (FDM) 3D Printers

Prototyping used to mean waiting weeks (or months) for costly tooling and complex machining. Now, with FDM 3D printing, KIMASTLE can turn digital designs into functional prototypes in a matter of hours. This means we can test, iterate, and refine parts early in the process, saving valuable time and reducing the risk of production delays.

We cover the full scope of product development—from prototyping to production. Learn more in our blog, From Prototyping to Production: How KIMASTLE’s 3D Printing Increases Efficiency with Robotics.

Smart Customization for Smarter Automation

Every automation assembly project comes with its own set of challenges, and that’s where our in-house Fused Deposition Modeling (FDM) capabilities shine. At KIMASTLE, we use FDM to produce durable, functional parts quickly and cost-effectively, without the long lead times of traditional manufacturing. Whether it’s custom end-of-arm tooling, robotic grippers, sensor mounts, or modular fixtures, our 3D printing solutions are tailored to meet your specific needs and scale with your production goals.

We offer a wide range of high-performance thermoplastics, including ABS, PC-ABS, TPU-95A, PLA, PETG-CF and PET-CF (carbon fiber-reinforced), PA6, PA12, PA-CF (nylon variants), polypropylene (PP), ASA, HIPS, PC, PVA, and more. Our standard print color is black, but other options are available depending on the material. Our FDM printers support sizes up to 16.5” x 11.75” x 15.5”, and custom color requests are welcome based on availability.

If you’re looking to increase efficiency, reduce cost, or simply need precision components fast, explore our full list of 3D printing materials and specs or you can read our latest article, Exploring Fused Deposition Modeling (FDM) in 3D Printing with KIMASTLE

Reducing Waste and Saving Costs

Additive manufacturing uses only the material needed. No cutting, no carving, no leftover stock. That’s not only more sustainable but also more economical, especially for short-run production or one-off parts. Instead of investing in costly injection molds or long machining cycles, we can 3D print what you need with minimal waste. This helps lower costs and speeds up timelines.

A Competitive Edge for Automation Companies in Michigan

As one of the leading automation companies in Michigan, KIMASTLE stays ahead by embracing forward-thinking technology. Our investment in 3D printing is just one way we’re delivering cutting-edge solutions for a wide range of industries, from automotive to medical and beyond.

With an eye toward the future, we’re continually exploring new materials and methods to improve strength, functionality, and sustainability in our parts. Whether you’re building a fully automated conveyor system, upgrading existing tooling, or starting from scratch, KIMASTLE is ready to help you design smarter with 3D printing.

A Look Ahead: What’s Next in 3D Printing for Automation?

3D printing technology is constantly evolving. New material innovations, like carbon fiber or glass fiber-reinforced polymers, are making it possible to print even stronger, lighter, and more complex parts. Combined with generative design and AI, the future of automation tooling is only getting more intelligent.

Want to see how far we’ve come? Take a step back in time with The Origins of 3D Printing, then imagine what’s next.

Partner with KIMASTLE for Smarter, Faster Automation

At KIMASTLE, 3D printing isn’t just an add-on. It’s a core part of how we approach plastic assembly automation. Our in-house capabilities and wide material range allow us to support industries with tailored, efficient, and innovative solutions.

If you’re ready to take your production process to the next level, partner with KIMASTLE, one of the most trusted automation companies in Michigan.

Let’s build something better. Reach out today and see how 3D printing and automation can reshape what’s possible for your business.