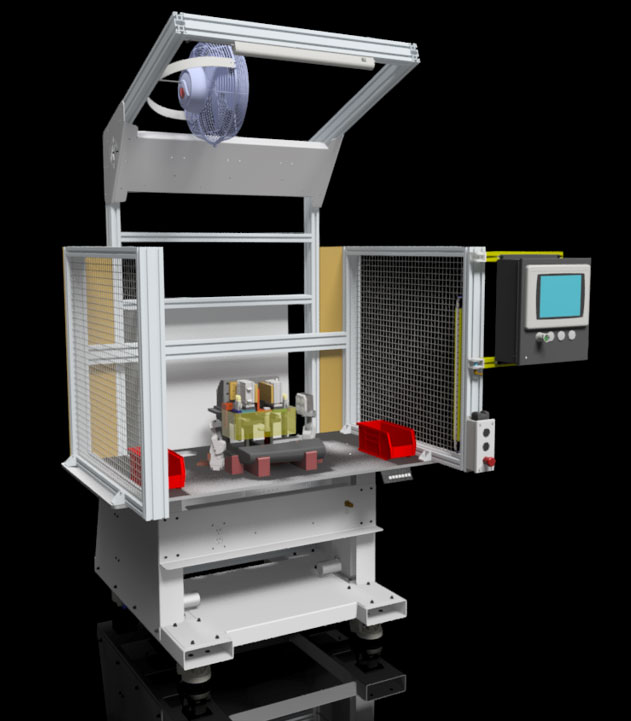

K-Base 2300 Series

The kimastle

K-Base,

is a standardized ergonomic assembly station that provides a cost-effective, high-quality manufacturing solution. KIMASTLE has provided assembly solutions for a magnitude of industries. With this knowledge, we have focused our efforts on the latest trends in the manufacturing industry. The two areas every top manufacturer focuses on are standardization and flexibility. Every manufacturer invests in tooling products that will help increase efficiencies within their process, and KIMASTLE understands how important this investment is to the success of the product and manufacturer. The K-Base is a standardized design that has many options and configurations to accommodate a large majority of today’s manually assembled products. The K-Base provides a high-quality powder-coated steel base with an extruded aluminum overhead structure that can accommodate many different types of tooling and automated controls. The aluminum plate worksurface supports a wide variety of tooling and its electric motor-controlled height adjustment offers extensive flexibility for all operators. This adjustable work surface can accommodate dedicated, subplate, and quick interchangeable tooling to provide a range of tooling solutions to competitively meet target price points.

Explore the possibilities with K-Base and configure your manufacturing solution by contacting a Kimastle Representative.

2300 (Base)

features

- Worksurface Dimensions: L30in x W48in

- Worksurface Material: 6061 Aluminum Tooling Plate

- Worksurface Ergo-Adjustment: 31in – 47in

- Worksurface Weight Capacity: 880lb

- Electric Motor QTY: Two [2]

- Casters Type: Heavy Duty Leveling Swivel

- Steel Base Color: RAL#910 Powder Coated (Option Customer Specified RAL#)

- Extruded Aluminum Overhead System Type: T Slot

- Pneumatic: One [1] Standard Quick Disconnect

- Standard Operator Features

- One [1] 120V Standard outlet with engineered phone ledge.

- One [1] Cooling Fan

- One [1] Low Energy High Output LED Work Light

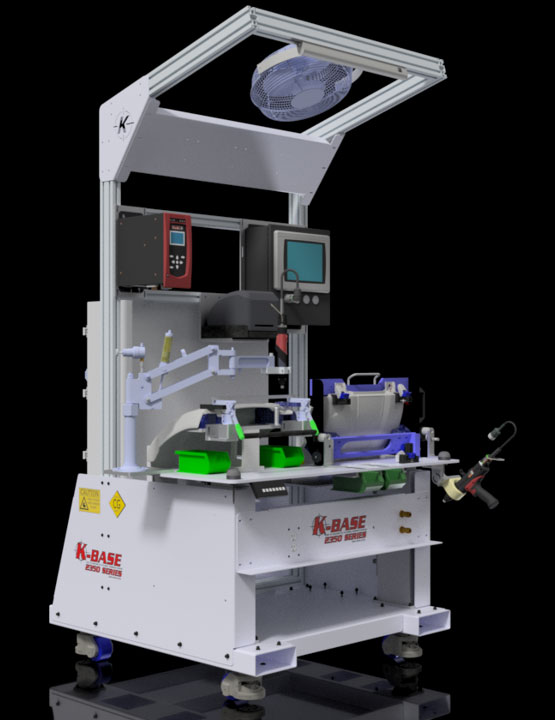

2350 (Base)

features

- Worksurface Dimensions: L30in x W48in

- Worksurface Material: 6061 Aluminum Tooling Plate

- Worksurface Ergo-Adjustment: 31in – 47in

- Worksurface Weight Capacity: 1700lb

- Electric Motor QTY: Four [4]

- Casters Type: Heavy Duty Leveling Swivel

- Steel Base Color: RAL#910 Powder Coated (Option Customer Specified RAL#)

- Extruded Aluminum Overhead System Type: T Slot

- Pneumatic: One [1] Standard Quick Disconnect

- Standard Operator Features

- One [1] 120V Standard outlet with engineered phone ledge.

- One [1] Cooling Fan

- One [1] Low Energy High Output LED Work Light

2300 and 2350 (Standard Optional)

features

- Worksurface Dimension: L30in x W60in

- Manual Operator INTERCHANGABLE TOOLING

- Controls

- HMI – Allen Bradly Panel View Plus 6.5in

- PLC – Allen Bradly Compact Logix L16 with Ethernet

- Electrical Enclosure – Standard 30in x 30in NEMA 12

- Pneumatic Valve Type – SMC

- Pneumatic Valve QTY – 6 station

1 + 1 CAVITY, MANUAL SCREW DRIVE ASSEMBLY STATION WITH POSITION FEEDBACK TECHNOLOGY

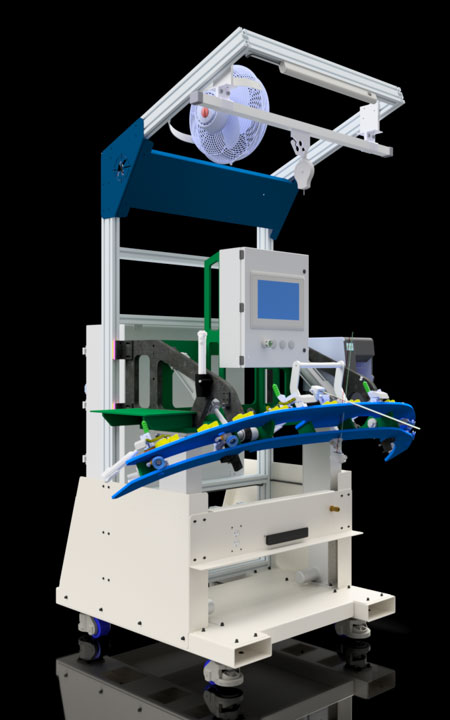

DUAL CAVITY PROGRESSIVE DRILL AND SCREW GUN STATION

SINGLE CAVITY FASCIA SNAP ASSEMBLY WITH ROTATE

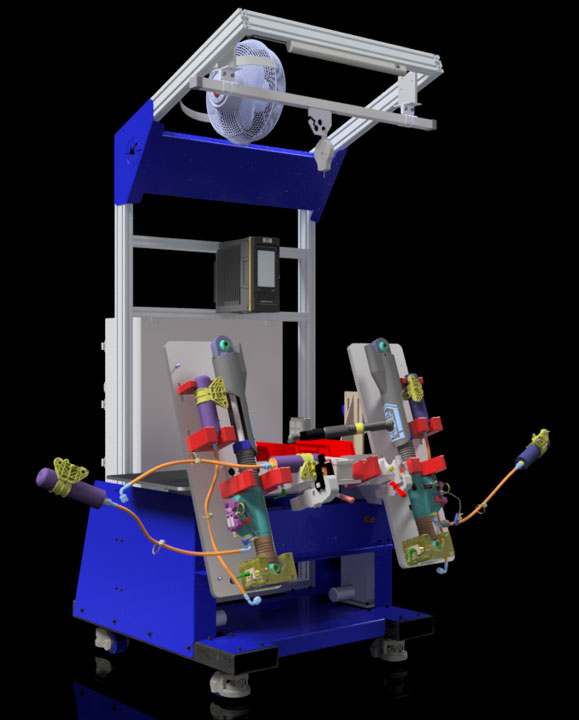

SINGLE CAVITY TORQUE GUN AND HAND WELDER STATION. (2) PERSON ASSISTED REMOVABLE TOOL PACKS, WITH (2) LEVEL HOLDING STATION

SINGLE CAVITY MANUAL SCREW DRIVE AND CAMERA TEST MACHINE

1 + 1 CAVITY, MANUAL LOAD SCREW DRIVE ASSEMBLY MACHINE

SINGLE CAVITY, MANUAL LOAD HOT AIR STAKE MACHINE

SINGLE CAVITY MANUAL LOAD SNAP ASSEMBLY STATION