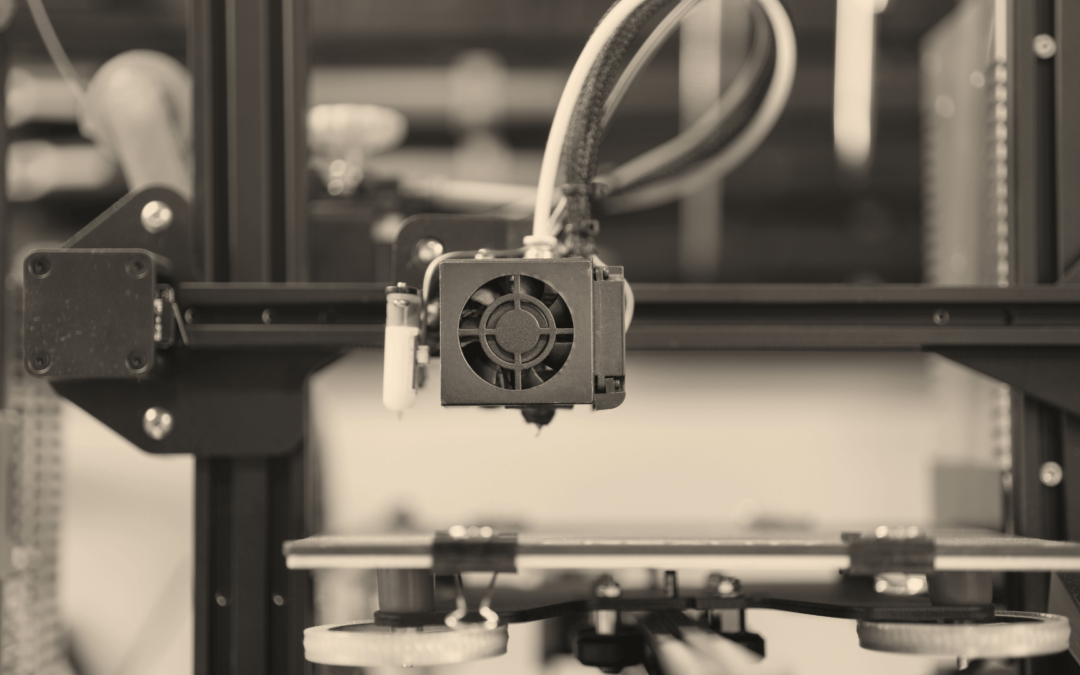

In the ever-evolving world of robotics, the integration of 3D printing technology has unlocked new frontiers of innovation and efficiency. At KIMASTLE, we are proud to offer extensive 3D printing services, utilizing Fused Deposition Modeling (FDM) to bring custom tooling solutions to life across various industries. Our state-of-the-art 3D printing capabilities not only streamline the prototyping process but also enable enhanced efficiency in production, shaping the future of advanced robotics systems.

The Power of Fused Deposition Modeling (FDM)

At the heart of our 3D printing services lies the Fused Deposition Modeling (FDM) technique. This cutting-edge technology allows us to create intricate and durable components by depositing successive layers of thermoplastic materials, such as ABS, PC-ABS, TPU-95A, PLA, HIPS, PET-CF, PETG, PETG-CF, Nylon, ASA, PC, PP, PVA, and reinforced materials like glass fiber and carbon fiber. With a vast array of material options and color choices, we can cater to the specific requirements of your robotics projects, ensuring optimal performance and aesthetics.

Accelerating Prototyping and Design Iterations

One of the most significant advantages of 3D printing in robotics is the ability to rapidly prototype and iterate designs. As highlighted in the research article “3D/4D printing in Advance Robotics Systems- Recent Developments and Applications,” “the use of 3D printers reduces the production time severalfold and allows for completing the necessary simulations and tests.” By leveraging our FDM 3D printing capabilities, we can swiftly create functional prototypes, allowing for essential testing, refinement, and validation before committing to full-scale production.

Enabling Customization and Complex Geometries

Traditional manufacturing methods often impose limitations on the complexity of designs, particularly when it comes to robotics components such as actuators, pneumatic muscles, and power transmission units. However, 3D printing breaks through these barriers, enabling the production of intricate, thin-walled, and cellular structures that were previously challenging or impossible to fabricate. This newfound design freedom empowers robotics engineers to push the boundaries of innovation, unlocking novel solutions and optimizing performance.

Streamlining Production and Reducing Lead Times

Beyond prototyping, 3D printing is revolutionizing the production process in robotics by significantly reducing lead times and enabling on-demand manufacturing. With our FDM 3D printing services, we can produce custom tooling and components with unparalleled speed and efficiency, facilitating quicker time-to-market and minimizing downtime. This agility is particularly valuable in dynamic industries where rapid adaptability and responsiveness are crucial for staying ahead of the curve.

At KIMASTLE, we are committed to harnessing the power of 3D printing to drive innovation and efficiency in the robotics industry. By combining our expertise in advanced manufacturing with cutting-edge 3D printing technologies, we empower our clients to revolutionize their robotics solutions, from prototyping to production.

Explore our extensive range of 3D printing materials and capabilities, and let us help you unlock the full potential of your robotics projects. Contact us today and get a quote!